Kashima Bearing Inc. founded in Osaka, Japan in 1953, initially operated as a plastic products company. However, it later focused on the production and sales of plastic rolling bearings, along with a small portion dedicated to ceramic and titanium bearings. The bearing brand is known as UKB.

UKB's plastic bearings are not injection-molded but rather manufactured through machining of plastic materials to ensure bearing precision. Depending on the specific requirements, UKB offers a variety of resin materials for the inner and outer races of their plastic bearings, such as phenolic resin, polytetrafluoroethylene (PTFE), ultra-high molecular weight polyethylene (UHMWPE), polypropylene, polyvinyl chloride (PVC), polyether ether ketone (PEEK), and carbon materials. Regarding the choice of ball materials between the inner and outer raceways of plastic bearings, UKB recommends options like stainless steel, glass, and ceramics. Among the ceramic ball options, there are four materials to choose from: aluminum oxide, zirconium oxide, silicon carbide, and silicon nitride.

Feature & Application

UKB plastic bearings find applications across various industries, ranging from semiconductor LCD, electronic communication, and electrical equipment to chemical equipment, medical devices, textile machinery, transportation equipment, environmental-related devices, and food machinery

Product Portfolio

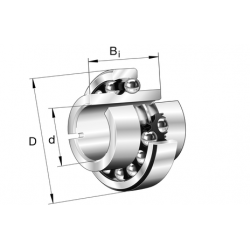

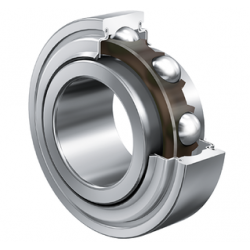

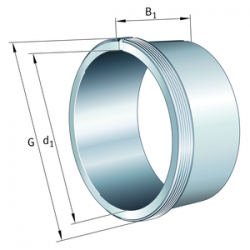

The product line of UKB plastic bearings includes deep groove ball bearings, thrust ball bearings, angular contact ball bearings, self-aligning ball bearings, miniature ball bearings, and custom plastic ball bearings.