In 1946, Nankai Seiko, a Japanese company, began producing and selling SMT brand ball bearings in Osaka. In 1965 and 1969, they exported ball bearings to the United States and West Germany, respectively. In January 1976, SMT started the production and sale of double-row angular contact ball bearings. In April of the same year, they began manufacturing stainless steel ball bearings and developed market applications, thereby establishing a mass production system and the bearing industry's first rapid delivery system based on inventory production. Three years later, in 1979, they started producing thin-walled ball bearings. SMT subsequently expanded its production capacity by establishing new bearing factories in Osaka in 1982, 1988, 1990, and 2007.

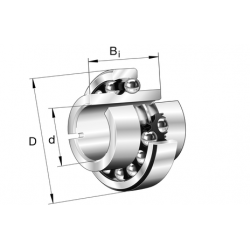

SMT continuously developed stainless steel bearings using different alloy materials such as AISI 440C, AISI 316L, AISI 304, and AISI 630, gradually solidifying SMT's leading position in the niche stainless steel bearing industry. In 2010, 2011, and 2015, they respectively developed and produced ceramic ball bearings, oil-free bearings, and flange bearing units. In 2018, they began manufacturing and selling heat-resistant stainless steel bearings and heat-resistant hybrid bearings. In 2019, they further expanded their product line with the addition of the 5200 and 5800 series double-row angular contact ball bearings. Throughout SMT's over 70-year history, they have continuously developed new products, and what's even more commendable is that these new products have met market demands, driving business sales and the company's continuous growth.

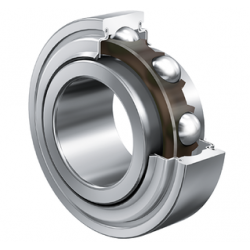

SMT bearings are primarily used in food and beverage equipment, office equipment, electric motors, household appliances, agricultural machinery, and more. The maximum outer diameter of the chrome and stainless steel bearings produced by SMT can reach 130 millimeters. Among them, SMT AISI 304 stainless steel ball bearings exhibit higher corrosion resistance compared to conventional SAE 52100 ball bearings, while SMT AISI 440C stainless steel bearings possess characteristics of high corrosion resistance and chemical resistance. SMT's high-temperature grease can be used for both 304 and 440C stainless steel bearings, further enhancing the stability of the bearings under high temperatures. Additionally, each component of SMT bearings can be designed with different materials, allowing for suitable bearing combinations based on specific application requirements.

Feature & Application

- The main applications of SMT bearings include food and beverage equipment, office equipment, electric motors, household instruments, agricultural machines, and various other industries.

- SMT has the ability to produce specialized and newly engineered bearings.

- SMT operations adhere to stringent quality control measures and undergo continuous modernization to meet all requirements

- We offer chrome and stainless steel bearings in sizes up to 130 mm outer diameter (OD).

- SMT AISI 304 stainless steel ball bearings exhibit significantly higher corrosion resistance compared to those manufactured from SAE 52100 bearing steel or AISI 440C stainless steel.

- SMT AISI 440C stainless steel bearings demonstrate excellent resistance to corrosion and chemicals, as well as remarkable stability in high-temperature environments.

- A heat-resistant grease is applied to AISI 304 and AISI 440C stainless steel ball bearings.

Product Portfolio

- 6000, 6000ZZ, 6000-2RS (Produce up to 6014)

- 6200, 6200ZZ, 6200-2RS (Produce up to 6214)

- 6300, 6300ZZ, 6300-2RS (Produce up to 6312)

- 5200 (Double Row Ball bearing)

- 16000 (narrow width) & 61800-61900 (Thin Radial Ball bearings)

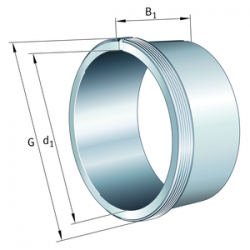

- 62200-63000 (euro width), 8000 & 87000 (extended inner ring),

- WC8000 & WC87000 (ND type - wide cup), and 88000 (extended inner ring) type bearings.

- GW1 –GW4, GW1X –GW4X, GW1SSX-GW4SSX (Guide Wheel bearings)

- Snap ring available on all 6000-6300 series (NR)

- R (inch series), EE (inch series), RLS (inch series)

- Strain Wave Bearings