In 1918, a perfect combination of excellent salesmanship and determined engineering once again emerged in the history of bearing entrepreneurship, leading to the creation of a great multinational bearing company, NTN, headquartered in Osaka. Let's talk about the two sales talents among the founders. Mr. Noboru Niwa, from a young age, aspired to become a businessman and possessed the aptitude for it. He founded a trading company before the age of 20. Niwa was not a smooth-talking salesperson; his sales characteristic was patiently discussing a topic for several hours. People who talked with him were often drawn to his enthusiasm. However, Niwa's ambition was not limited to selling imported bearings. It was only in 1923, at the age of 24, that he collaborated with engineer Mr. Jiro Nishizono to establish the NTN brand and commence bearing manufacturing in Japan.

Next, let's briefly discuss Mr. Nishizono, an engineer who is honored as the father of NTN. One year older than Mr. Niwa, Mr. Nishizono started working at Tomioka Ironworks when he was 19 years old. Just two years later, in 1918, he established Nishizono Ironworks, where he repaired bearings brought from spinning mills and began researching bearing manufacturing. Although Mr. Nishizono didn't receive formal engineering training, he possessed innate talent in manufacturing engineering. Remarkably, he had a clear mind and dedicated himself day and night to the study of bearing manufacturing.

When these two young and passionate individuals with a deep fascination for bearings came together, along with the favorable environment of high-priced imported bearings from Europe and America, NTN's success was almost a natural outcome. Additionally, the courage of NTN's two founders cannot be underestimated. In 1922, when Mr. Niwa heard about a maritime accident involving a foreign ship carrying bearings at Yokohama Port and learned that the ship came from Sweden, he decisively won the bid and purchased all the bearings on the ship. He entrusted the repair work to Mr. Nishizono and sold the repaired bearings to make a profit. It is not difficult to imagine that they also gained valuable knowledge about bearings through this process.

Then, Mr. Niwa decided to challenge the domestic production of bearings in Japan and focused on the future of the bearing business. He constantly asked himself a question: "Why rely on imported bearings and spend 5 yen per bearing when a Japanese company can manufacture them for 1 yen each?" As a result, Mr. Niwa used the profits from bearing repairs to purchase three grinding machines and asked Mr. Nishizono to learn bearing manufacturing techniques.

During the initial stages of NTN's domestic bearing production, due to insufficient knowledge of bearing materials and processes, many defective products were inevitably produced. In many cases, the products were returned by customers because they were unsuitable for use. The two young founders of NTN continuously learned from bearing failures, improved product quality, actively responded to business challenges, and gradually put NTN's domestic bearing business on the right track.

The "Frontier Spirit" in the DNA of NTN's founders gradually evolved into the cultural essence of NTN as a company. This concept, often referred to as the "Frontier Spirit," involves leaving the relative safety of villages or cities and venturing into unsettled territories. It is what we commonly refer to as stepping out of one's comfort zone, requiring courage, creativity, and perseverance.

Another pillar of NTN's corporate culture is the "Coexistence and Co-prosperity Spirit." This philosophy allowed NTN's manufacturing footprint to rapidly expand across Japan after the company's establishment and gradually extend worldwide in the 1950s and 1960s. NTN subsequently established subsidiaries in the United States, France, Canada, Germany, Singapore, and Hong Kong. At the same time, NTN's products achieved significant milestones. For example, in 1937, NTN bearings were used in the first domestically manufactured aircraft in Japan, flying from Tokyo to London, showcasing the superiority of NTN's bearings and establishing their capabilities in aircraft bearing technology.

Of course, NTN also benefited from the input of advanced technologies from Europe and America. For instance, after World War II, Deming made significant contributions to promoting statistical quality control in Japan, leading to a leap in the country's product quality standards.

Feature & Application

- Automotive Industry: NTN bearings are extensively used in various automotive applications, including engine components, transmissions, wheel hubs, differentials, steering systems, and electric motors.

- Industrial Machinery: NTN bearings are widely employed in industrial machinery, such as pumps, compressors, conveyors, generators, printing machines, textile machinery, packaging equipment, and machine tools.

- Aerospace Industry: In the aerospace sector, NTN bearings are utilized in aircraft engines, landing gears, airframe components, control systems, and helicopter rotor systems.

- Construction Equipment: NTN bearings are commonly used in construction machinery like excavators, bulldozers, cranes, loaders, and concrete mixers.

- Agricultural Machinery: Bearings from NTN are employed in agricultural machinery, including tractors, harvesters, sprayers, and tillage equipment.

- Mining and Quarrying: NTN bearings are utilized in mining equipment, such as crushers, screens, conveyors, and excavators.

- Renewable Energy: With the growing focus on renewable energy sources, NTN bearings are used in wind turbines and solar power systems.

- Railways and Transportation: NTN bearings are employed in railway vehicles, locomotives, freight cars, and passenger coaches.

- Medical Equipment: In the medical field, NTN bearings are used in various equipment, such as imaging systems, surgical devices, dental equipment, and laboratory instruments.

Product Portfolio

NTN offers a diverse range of bearing products to cater to various industries and applications. Their product portfolio includes:

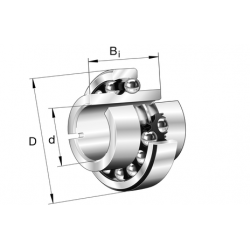

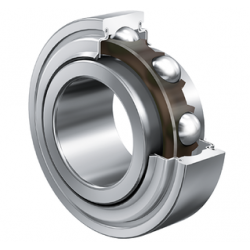

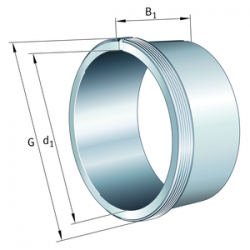

- Deep Groove Ball Bearings, Angular Contact Ball Bearings, Cylindrical Roller Bearings, Tapered Roller Bearings, Spherical Roller Bearings, and Needle Roller Bearings

- Thrust Bearings: NTN offers various types of thrust bearings, including ball thrust bearings, cylindrical roller thrust bearings, and spherical roller thrust bearings.

- Mounted Units & Pillow Blocks: NTN manufactures a range of mounted units and pillow blocks, which are ready-to-install bearing units.

- Precision Bearings: NTN offers precision bearings, including angular contact ball bearings, cylindrical roller bearings, and ball screw support bearings, for applications that require high accuracy and precision, such as machine tools and precision equipment.

- Automotive Bearings: NTN supplies a wide range of bearings specifically designed for automotive applications. These include wheel hub bearings, tensioner bearings, driveshaft bearings, and transmission bearings.

- Constant Velocity Joints (CVJ): NTN manufactures CVJs, which are used in automotive drivetrain systems to transmit torque while accommodating angular misalignment.

- Maintenance Tools and Accessories: In addition to bearings, NTN provides a range of maintenance tools and accessories to facilitate bearing installation, lubrication, and maintenance. These include bearing heaters, pullers, greases, and seals.