In 1914, during the outbreak of the First World War, Takehiko Yamaguchi, with the assistance of Takashi Hirakawa and others, founded Nippon Seiko Goshi Kaisha, a joint venture company in Japan, to start the trial production of bearings. In 1916, the company was reorganized and established as Nippon Seiko Kabushiki-gaisha (NSK). The founder, Takehiko Yamaguchi, naturally became the first president.

In 1891, at the age of 22, Takehiko Yamaguchi graduated from the Tokyo Industrial University. He joined Yasuda Bank as an engineer upon the recommendation of Takashi Hirakawa. Starting from 1896, he worked on technical acquisitions in Cleveland, Ohio. After returning to Japan, he established Fukagawa Wire Nail Factory and developed Japan's first round nail in 1898. Due to difficulties in importing raw materials, the factory closed in 1902. Later, he successively founded Sanbu Shokai and Nihon Sanjo Company to engage in oxygen manufacturing. Finally, in 1914, NSK, a precision processing enterprise, was established. This shows that Takehiko Yamaguchi's entrepreneurial path was not without challenges. As the saying goes, there are often excellent horses, but it is difficult to find a competent judge. In today's perspective, Takashi Hirakawa could be considered as a competent judge. Not only was he a successful banker, but he also served as Japan's Minister of Finance and Prime Minister. During his tenure, he implemented expansionary fiscal policies and was known as the "Japanese Keynes."

Compared to European and American bearing companies, NSK's initial focus was on bearing manufacturing rather than technological innovation. The company continuously expanded its factories worldwide and, over the past century, has achieved numerous firsts in the Japanese bearing industry, some of which are even global firsts. The developmental history of NSK can be roughly divided into six stages:

1. The first stage, from the company's founding to 1944, saw NSK's support for Japan's industrial modernization. As a bearing manufacturer, NSK played a crucial role in establishing the rolling bearing industry in Japan. During this period, NSK achieved many firsts in the Japanese bearing industry. For example, in 1917, NSK published Japan's first bearing catalog. In 1918, it manufactured a double-row thrust ball bearing with an outer diameter of 510mm, used for crane slewing support. In the 1930s, NSK developed the first double-row cylindrical roller bearings for rolling mills, bearings for aviation engines, and bearings for gas-powered locomotives of the Japanese National Railway

2. The second stage of NSK's development, from 1945 to 1970, primarily focused on supporting Japan's post-war reconstruction and rapid economic growth. NSK concentrated on improving product quality, increasing production capacity, and diversifying its product range. It took the lead in mass-producing bearings for aircraft jet engine spindles, spinning machine spindles, miniature bearings for cameras, ball screw steering systems, and stainless steel miniature bearings capable of operating at speeds up to 300,300 RPM for air turbines.

3. The third stage of NSK's development, spanning roughly from 1971 to 1985, was particularly crucial. In order to adapt to Japan's industrial mechanization and internationalization, NSK decided to comprehensively enter the overseas market and transform into a company driven by creative technological development. This included expanding its production system in Japan and establishing joint ventures in the United States, wholly-owned subsidiaries in Toronto, Canada, and London, England, as well as sales companies in Singapore and France, and a representative office in South Korea.

4. After more than a decade of global expansion, NSK entered the fourth stage of development, which lasted roughly until the early 21st century. During this stage, NSK achieved success in fierce global competition and further strengthened its global technological system.

5. Subsequently, with the rise and rapid growth of China and emerging markets, NSK entered the fifth stage of development, which lasted until 2016. During this phase, NSK rapidly increased its investments in China and emerging markets and achieved true manufacturing localization. It established more than ten production bases, investment companies, and research and development centers in locations such as Kunshan, Suzhou, Changshu, Zhangjiagang, Shenyang, and Hefei in China. It also established factories in Mexico and India.

6. Like most multinational corporations, after achieving remarkable growth, NSK shifted its strategic focus to sustainable development starting from 2016. This marked the beginning of the sixth stage of NSK's development. The company introduced the world's first wireless charging wheel motors, high-efficiency motor bearings, and developed next-generation steering system control software.

Feature & Application

NSK bearings are widely used in various industries and applications due to their high quality, precision, and reliability.

- Automotive Industry: NSK bearings are extensively used in automotive applications, including engines, transmissions, wheel hubs, steering systems, and electric motors.

- Industrial Machinery: NSK bearings are employed in a wide range of industrial machinery, such as machine tools, pumps, compressors, conveyors, and printing presses.

- Aerospace: NSK bearings find application in the aerospace industry for aircraft engines, landing gears, airframe components, and navigation systems.

- Construction and Mining Equipment: NSK bearings are utilized in construction machinery and mining equipment, including excavators, loaders, bulldozers, and crushers.

- Electric Motors and Generators: NSK bearings are used in electric motors and generators for various applications, including power generation, industrial machinery, and household appliances.

- Medical Equipment: NSK bearings are employed in medical equipment such as surgical instruments, dental tools, imaging devices, and laboratory equipment.

- Railways: NSK bearings are extensively used in railway systems, including locomotives, train carriages, and rail infrastructure.

- Wind Turbines: NSK bearings play a crucial role in wind turbine applications, supporting the rotor, generator, and gearbox components.

Product Portfolio

NSK offers a comprehensive product portfolio that encompasses a wide range of bearing types and related products.

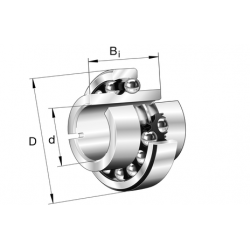

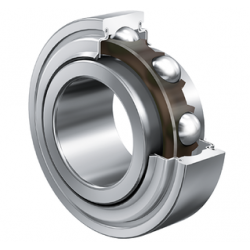

- Ball Bearings: NSK manufactures various types of ball bearings, including deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, and thrust ball bearings.

- Roller Bearings: NSK produces different types of roller bearings, such as cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and needle roller bearings.

- Precision Bearings: NSK offers precision bearings designed for high-precision applications that require extremely tight tolerances and accurate rotational performance. This includes precision angular contact ball bearings, super precision cylindrical roller bearings, and precision machine tool spindle bearings.

- Automotive Bearings: NSK is a leading supplier of bearings for the automotive industry. Their automotive bearing portfolio includes wheel hub bearings, clutch release bearings, tensioner and idler bearings, and driveshaft bearings, among others.

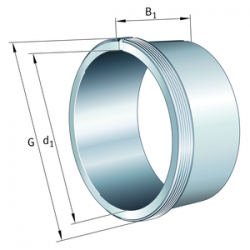

- Integrated Units: NSK develops integrated bearing units that combine a bearing and housing into a single assembly. These units simplify installation, reduce maintenance requirements, and ensure proper alignment and performance.

- Linear Motion Products: NSK offers a range of linear motion products, including linear guides, ball screws, linear actuators, and linear guides for maintenance-free operation. These products are used in various industries, including automation, machine tools, semiconductor manufacturing, and medical equipment.

- Maintenance Tools and Condition Monitoring: NSK provides a range of maintenance tools and condition monitoring systems to assist with bearing installation, inspection, and maintenance. This includes bearing heaters, bearing pullers, lubrication systems, and vibration analysis tools to monitor and diagnose bearing performance.

- Dental Bearings: NSK manufactures specialized bearings for dental handpieces, dental turbines, and dental scalers. These bearings are designed for smooth, precise, and quiet operation in dental applications.