The linear guide brand NB is the abbreviation of "Nippon Bearing," with the company name Nippon Bearing Co., Ltd. The predecessor of Nippon Bearing Co., Ltd. was Yamazaki Steel Processing Plant, established in 1939 in Ojiya City, Niigata Prefecture, Japan. It initially operated as a cooperative factory for Tsugaru Co., Ltd., manufacturing gauges and machinery equipment. In 1959, it became a corporate organization and changed its name to Yamazaki Seiki Co., Ltd. The following year, in 1960, it developed sliding bushings and began the production and sales of linear motion systems. In July 1963, the company officially changed its name to Nippon Bearing Co., Ltd. and expanded its factory. In 1987, NB America Corp. was established in Chicago, USA. In 2002, NB Europe B.V. was established in Amsterdam, the Netherlands. In 2012, NB (Shanghai) Trading Co., Ltd. was established in Shanghai, China. In 2015, NB Malaysia Sdn. Bhd. was established in Kuala Lumpur, Malaysia.

Compared to the common rotary motion in the bearing industry, the application of bearing mechanisms in linear motion is like taking a different approach. First, we define linear motion as a technology that uses "sliding motion" or "rolling motion" to change power and displacement. The linear guides or linear motion systems commonly discussed in the bearing industry are bearing mechanisms that achieve linear reciprocating motion based on the rolling motion of balls or rollers. Compared to sliding motion, rolling motion has much less frictional resistance and enables smooth linear motion. Additionally, due to the high-precision grinding of the rolling elements, even in long conveying surfaces and high-load environments, the precision and service life of the system can be ensured.

Feature & Application

NB product series of linear motion systems can be categorized as following:

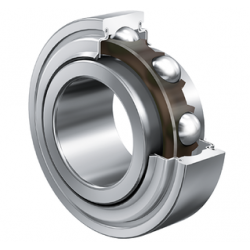

- The first category is rolling guides, which are high-precision and high-rigidity linear guide bearings that operate based on the rolling principle. They have low friction, no creeping, and can achieve smooth linear motion even under high load conditions. They are widely used in industrial machinery, including ultra-precision machinery.

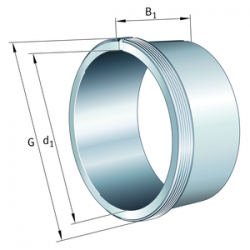

- The second category is ball splines, which are linear motion devices that utilize the rolling of steel balls. They can withstand both radial loads and torque, making them widely used in transportation systems and robotics.

- The third category is slide bushings, which also achieve linear motion by utilizing the rolling of steel balls. Due to their simple structure and low friction linear motion, they are widely used in transportation systems, food machinery, and semiconductor manufacturing equipment.

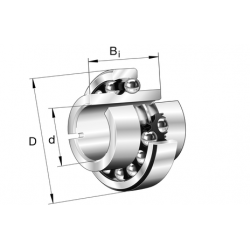

- The fourth category is self-aligning bushings, which have automatic self-aligning capabilities. They are widely used in various fields such as factory automation equipment, machine tools, electrical devices, optical equipment, and measurement equipment.

- The fifth category is stroke bushings and sliding-rotating bushings, which can guide not only linear motion but also combined linear and rotational motion. These products are designed to accommodate both types of movements efficiently.

- The sixth category is crossed roller guides, which utilize precision rollers in a non-recirculating manner for linear motion. These bearings are primarily used in applications that require high precision, such as optical machinery and measuring instruments.

- The seventh category is the intelligent combination actuator. It utilizes a U-shaped guide with a sliding block on the inner side that integrates a sliding block and a ball screw nut. Compared to traditional positioning stages, this design saves space. Additionally, the U-shaped guide provides high rigidity and is suitable for cantilever structures, as it exhibits low bending and deflection.

- This design meets the requirements of high load capacity, high precision, and high rigidity.