The IKO bearing brand originated in Japan and is known as Nippon Thompson Co., Ltd. The company's predecessor was the First Nippon Chemical Industry Company, established in 1950 as a trading company for bearing and mechanical components. In 1956, they formed an alliance for the sales of needle roller bearings and began developing them. By 1959, they started mass production of needle roller bearings, becoming the first manufacturer of such bearings in Japan. Another strong product line of the IKO brand is linear guides. In 1983, IKO became the first bearing company in the world to produce cylindrical roller type linear guides.

In 1963, the company changed its name to Nippon Thompson Co., Ltd., and registered the IKO bearing brand in the same year. The three letters in the IKO brand represent Innovation, Know-how, and Originality, which reflect the company's philosophy of providing high-quality products tailored to customer needs through integrated sales, engineering, and manufacturing.

Regarding collaborations with other bearing companies, IKO successfully expanded its production capacity through a four-year business cooperation with SKF in 1969. In 1973, they received capital support from Nachi-Fujikoshi, further expanding their production capacity.

IKO needle roller bearings are widely used in transportation equipment such as automobiles, motorcycles, railway vehicles, and aircraft. In the application scenarios of off-road motorcycles, which require high load capacity under harsh conditions, IKO needle roller bearings' unique design not only meets the high load requirements but also adopts a lightweight and compact design to enhance performance. IKO crossed roller bearings are applied in precision and industrial equipment, including medical CT equipment, small wind power equipment, robots, and mechanical engineering equipment. In addition to offering rotary solutions, IKO also focuses on linear motion solutions, providing low-friction movement and precise positioning capabilities. For example, they are used in linear moving doors for subways, medical surgical robotic arms, linear motion workbenches, and meeting the high-speed and high-precision requirements of semiconductor equipment.

As a manufacturer specializing in the niche market of needle roller bearings and linear guides, IKO has a unique global presence. Manufacturing facilities are primarily concentrated in Japan and Vietnam, while sales subsidiaries are strategically located in major countries across Asia, Europe, North America, and Central and South America, including China, South Korea, Thailand, the Netherlands, France, Germany, the United Kingdom, Spain, the United States, Canada, and Brazil. With this extensive global network of distributors, IKO products are introduced to the global market.

Feature & Application

IKO needle roller bearings find extensive applications in transportation equipment such as automobiles, motorcycles, railway vehicles, and aircraft.

IKO crossed roller bearings are utilized in precision and industrial equipment, including medical CT equipment, small wind power equipment, robots, and mechanical engineering equipment.

Linear guides manufactured by IKO are employed in various applications, such as linear moving doors in subways, medical surgical robotic arms, and linear motion workbenches.

Product Portfolio

IKO specializes in high-quality needle roller bearings, linear motion rolling guides, precision positioning stages, and machine components.

Linear Motion Rolling Guides: IKO's linear motion rolling guides reduce friction in linear motion mechanisms. This includes linear guides and linear roller ways, as well as shaft guides based on ball spline technology.

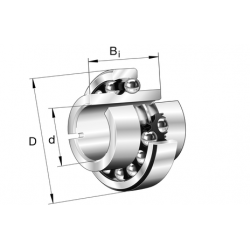

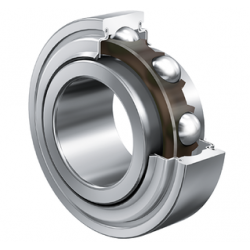

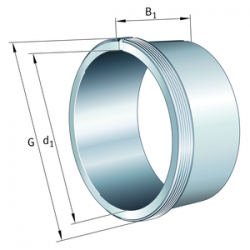

Needle Roller Bearings: Needle roller bearings feature a low cross-sectional height and high load-carrying capacity. They facilitate rotational motion and incorporate thin needle-shaped rollers as rolling elements. Due to their small size, these bearings help reduce the overall size of machines.

Precision Positioning Stages: Precision positioning stages, driven by ball screws or motors, combine precision machining technology with electronic devices. They are designed to provide accurate positioning and feature embedded beds and sliding stages.

Many products utilize IKO's patented C-Lube technology. This built-in lubrication system ensures maintenance-free operation for distances of up to 20,000 kilometers or even longer.