IJK (Inoue Jikuuke Kogyo) Bearing Co., Ltd., was established in Osaka, Japan, in 1944. In 1949, the company officially registered IJK as its bearing trademark. From its inception, IJK positioned itself as a specialized and precise small-scale company. Apart from a business alliance with NSK in 1961, IJK has consistently focused on the research, development, and production of miniature, high-speed precision bearings, as well as high-speed electric tool bearings. Its product range includes both standard and non-standard bearings.

IJK currently has two production bases. The first base, established in Tondabayashi, Osaka, in 1968, serves as the company's headquarters. The second base is located in Sakai City, Osaka Prefecture, and consists of two factories built in 2006 and 2012, respectively. Compared to other Japanese bearing brands established around the same time, IJK's development can be considered slow. However, it is precisely this "slow development" that has allowed IJK to steadily enhance its product development and manufacturing quality, thereby solidifying its core competitive advantage of high-quality bearings in the market.

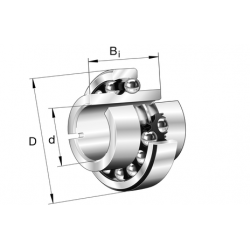

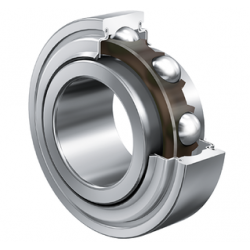

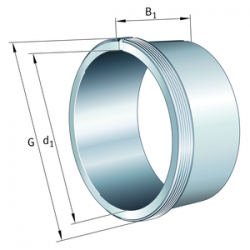

Now, let's discuss the product composition, company's strategic philosophy, and how IJK has consistently pursued the ultimate quality of bearings over the years. IJK primarily develops and produces six major types of bearing products. The first category is single-row deep groove ball bearings, mainly used in electrical components such as automotive transmissions, motors, household, and office equipment. The second category is self-aligning ball bearings, primarily applied in spinning machines and X-ray guide shafts. The third category is magnetoelectric motor bearings, used in small generators (magnetic controllers), gyroscopes, and other instruments. The fourth category is angular contact ball bearings, mainly used in machine tools, precision machinery, semiconductor equipment, and industrial machinery. The fifth category includes multi-row angular contact ball bearings, applied in auxiliary equipment for automobile engines, compressors, and gearboxes. The sixth category is special specification bearings, primarily used in bicycle hubs, chip mounting, and semiconductor equipment. In addition to producing standard bearing products, IJK excels at providing customized bearing products and engineering solutions for its customers. In terms of manufacturing capabilities, IJK's ultra-precision angular contact ball bearings produced through automated production lines are highly competitive in the market.

Feature & Application

- A large portion of production is dedicated for a large Japanese Ball Bearing company

- In addition to the standard sizes mentioned, IJK offers a wide variety of special bearing products and welcomes your special requirements

- Manufactures up to 75mm OD

- High quality bearings for precision motors meet the various needs of well-known electric appliance manufacturers

- 386 Employees across three locations, and two production facilities

Product Portfolio

- Miniature ball bearings

- 1200, 1300, 2200, 2300 (Self-Aligning Ball bearings)

- 5200, 5300 (Double Row Angular Contact Ball bearings)

- 7000, 7200 (Angular Contact Ball bearings)

- KP-KSP, DPP, DW-DSP, 500, and P (Aircraft Series bearings)

- 61700, 61800, 61900 (Thin Radial Ball bearings)

- R (Inch Series)

- 8000 & 87000 (extended inner ring)

- WC8000 & WC87000 (ND type - wide cup), and 88000 (extended inner ring) type bearings