In 1883, in the town of Schweinfurt, Germany, Friedrich Fischer founded FAG (Fischer Aktien-Gesellschaft) and invented the steel ball grinding machine. This invention was a significant milestone in the mass production of high-precision steel balls, which had a groundbreaking impact on the development of rolling ball bearings. Prior to Fischer's invention, steel balls were mainly imported from England, resulting in high prices and low quality. Fischer became the first person in the world to control the dimensional tolerance of steel balls within 0.02 millimeters and achieve a highly round shape.

As a result, Fischer earned the title of the father of modern ball bearings. With the establishment of his company, Fischer achieved commercial success through technological patents. However, this success also attracted fierce competition from other companies in Schweinfurt, similar to the situation faced by private enterprises in many countries. Fortunately, Fischer held the patent for the steel ball grinding machine, allowing him to collect patent royalties from his competitors and gain a certain competitive advantage.

Unfortunately, Fischer's health was poor, and he passed away prematurely at the age of 50 due to heart disease. Adding to the unfortunate circumstances, he had no children or successors. Consequently, in the ten years following his death, FAG company faced managerial challenges and difficulties.

This patented invention attracted numerous investors, and Wingquist personally visited hundreds of customers, demonstrating the working principle of his self-aligning ball bearings and how they addressed technical challenges. I have found a photo from 1909 showing Wingquist testing SKF bearings on a Scania truck. Within a few months, SKF received numerous orders in Sweden. Subsequently, SKF swiftly applied for and obtained patent authorizations in ten countries, including France, Germany, the United Kingdom, and the United States. This patent invention marked the immediate start of SKF's global expansion.

In the 20th century, after the passing of its founder Fischer, FAG company went through a period of uncertainty. In 1909, another family-owned company from Schweinfurt, named Schaefer, merged with FAG. The founder of this company was Georg Schaefer, and it was established in 1904, 21 years after FAG. Despite being founded much later, Schaefer company demonstrated high efficiency and managed to acquire FAG just five years after its own establishment.

In 1919, Georg Schaefer Jr. joined his father's company after World War I. After his father's death in 1925, he took over the management of FAG (Fischer Aktien-Gesellschaft) company. Germany's defeat in World War I, including unfavorable international tariff agreements, made it difficult for German bearing companies to thrive. For example, at that time, the tariff for German exports to the United States was 30%, while the tariff for foreign products entering the German market was only 5%-8%. Additionally, SKF from Sweden merged with seven bearing companies in the town of Schweinfurt, which eventually became the predecessor of SKF in Germany. These circumstances posed internal and external challenges for Georg Schaefer Jr.

After declining SKF's acquisition offer, led by Georg Schaefer Jr., FAG became the only independent German bearing company in Schweinfurt. In the 1930s, during the peak of the economic crisis and high unemployment rates in Germany, FAG defied the odds and expanded its business, actively venturing into overseas markets, including the Soviet Union. The turning point for the German bearing market came during World War II when FAG became a major supplier to the German war industry. Its bearing business reached unprecedented heights, employing 12,000 workers.

However, the good times did not last. Due to FAG's significant role in the German war industry, its factories experienced 15 bombings by the Allied forces towards the end of World War II, resulting in the destruction of 85% of the facilities. After the war, Georg Schaefer Jr. was initially stripped of the management rights to FAG. However, just two years later, he regained control because the United States Military Government in Germany recognized the need for the reconstruction of the German economy, particularly the bearing industry. Thus, Georg Schaefer Jr. once again led FAG through a seven-year process of factory reconstruction, with many departments operating outdoors. By 1955, FAG experienced a resurgence in Schweinfurt, employing 8,300 people.

In 1953, FAG established its first overseas factory in Stratford, Canada. From there, FAG embarked on its journey to become a global enterprise. It subsequently established sales companies in Italy, Brazil, Portugal, India, Austria, and the United States. Additionally, FAG was among the earliest bearing multinational companies to enter the Chinese and South Korean markets. After Georg Schaefer Jr.'s passing in 1975, the third generation of the Schaefer family took over the management of FAG. However, the Schaefer family departed from the FAG management team in 1993, and in 2001, FAG was acquired by INA company.

Feature & Application

FAG bearings have a wide range of applications across various industries. Some of the common applications of FAG bearings include:

- Automotive Industry: FAG bearings are used in automobiles, including passenger cars, trucks, and commercial vehicles.

- Industrial Machinery: FAG bearings are utilized in various industrial machinery such as pumps, compressors, gearboxes, motors, fans, conveyors,and agricultural equipment.

- Aerospace and Defense: FAG bearings are employed in aircraft, helicopters, missiles, and defense systems.

- The services provided by SKF include technical support, maintenance services, condition monitoring, and training.

- Energy and Power Generation: FAG bearings are used in power plants, wind turbines, hydroelectric systems, and other energy generation facilities.

- Railways and Transportation: FAG bearings are found in locomotives, trains, trams, and other rail vehicles.

- Heavy Machinery and Construction: FAG bearings are employed in heavy machinery used in construction, mining, and material handling equipment.

- Steel Industry: FAG bearings are used in steel mills for various applications such as rolling mills, continuous casting machines, and other equipment used in the production of steel.

- Paper and Printing Industry: FAG bearings are utilized in printing presses, paper mills, and packaging machines, ensuring precise movement and reliable performance.

- Marine and Offshore: FAG bearings are employed in marine applications such as ship engines, propellers, and offshore drilling equipment.

- Medical Equipment: FAG bearings are used in medical devices and equipment such as X-ray machines, MRI scanners, surgical tools, and dental equipment.

Product Portfolio

FAG, now a part of Schaeffler Group, offers a comprehensive product portfolio that includes various types of bearings and associated products.

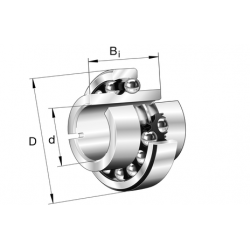

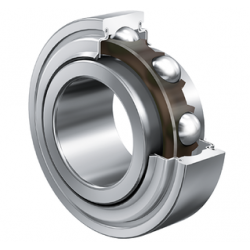

- Ball Bearings: FAG manufactures a wide range of ball bearings, including deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, and thrust ball bearings.

- Roller Bearings: FAG produces different types of roller bearings, such as cylindrical roller bearings, spherical roller bearings, tapered roller bearings, and needle roller bearings.

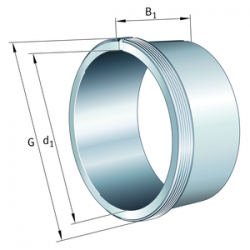

- Bearing Units: FAG offers a variety of bearing units, including plummer block housings, flanged units, take-up units, and insert bearings.

- Automotive Bearings: FAG specializes in automotive bearings for various applications in the automotive industry. This includes wheel bearings, tensioner bearings, clutch release bearings, transmission bearings, and other specialized bearings for automotive systems.

- Precision Bearings: FAG offers a range of precision bearings designed for high-speed and high-precision applications, such as machine tools, aerospace, and medical equipment.