EZO, a brand known for its ultra-miniature bearings, is a company named Hokkaido Seiko Co., Ltd., founded by Hidekazu Kobayashi. Kobayashi still serves as the chairman of the company and actively participates in the decision-making process. Established in 1969 in Hokkaido, Japan, although the company's history may not be long, EZO products have made a significant impact in the field of ultra-miniature precision bearings.

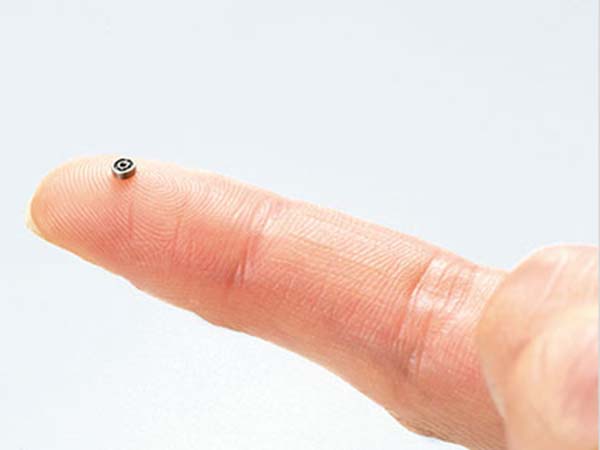

EZO's mass-produced ultra-miniature bearings have a minimum inner diameter of 0.6 millimeters, an outer diameter of 2.5 millimeters, a steel ball diameter of 0.5 millimeters, and a chamfer of 50 micrometers on the inner and outer diameters. The static and dynamic loads are 50 Newtons and 11 Newtons, respectively. Under oil lubrication conditions, the maximum speed can reach 152,000 RPM, which is equivalent to 2,533 rotations per second. Since the bearing weighs only 20 milligrams, I boldly speculate that this 0.6 millimeter inner diameter bearing might be the most expensive bearing in the world when calculated in kilograms.

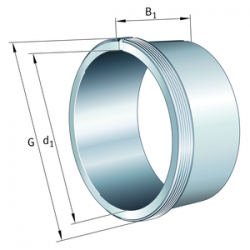

EZO miniature bearings have been exported to the European and American bearing markets since the 1970s. It is worth mentioning the sales company of EZO, Sapporo Precision Co., Ltd., established in 1960. In simple terms, EZO products are manufactured by Hokkaido Seiko Co., Ltd. and sold globally by Sapporo Precision Co., Ltd. Throughout EZO's development over half a century, they acquired Toyo Chokaizaki Seisakusho Co., Ltd. in 1985 to obtain ring turning capabilities. In 1990, they also acquired Hokkaido Owang Co., Ltd., securing precision steel ball manufacturing. In 1994, EZO established Kobayashi Precision Sealing Components Co., Ltd. in Zhejiang, China. Thus, EZO not only possesses the grinding and assembly capabilities required by bearing manufacturers but also vertically integrates turning, steel ball, and sealing processes to ensure precise manufacturing of their products.

Since the establishment of the Hokkaido headquarters factory, EZO has undergone several expansions, increasing production capacity and developing the ability to grind and assemble thin-walled bearings. This has enabled EZO to continuously overcome the challenges in the bearing industry. In 2002, EZO established the Equipment Maintenance and Development Department, forming a unique equipment maintenance system. EZO's expansion of overseas production bases is limited to China. They invested in Shanghai Precision Bearing Company in 1993 and established Hokkaido Precision Bearing Co., Ltd. in Harbin in 2011, maintaining the same level of manufacturing precision and technological capabilities as their Japanese factories.

Feature & Application

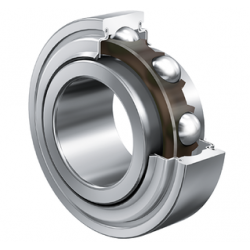

EZO's ultra-miniature bearings are suitable for applications that require high-speed rotation, low friction torque, low vibration, and low noise.

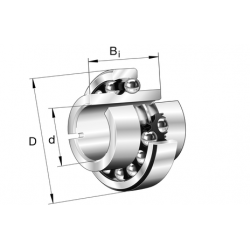

The flanged ultra-miniature, miniature, and small ball bearings have flanges on their outer rings for axial positioning. These bearings are commonly used in hard disk drives, stepper motors, fan motors, encoders, DVD spindles, small motors, and pulleys.

As for thin-walled bearings, they use multiple small-diameter balls, which enable low friction torque, high rigidity, and high rotational precision. In practical applications, hollow shafts can be used with thin-walled bearings to reduce weight. They are widely used in robotics, medical equipment, office equipment, transportation devices, optical/video equipment, measurement instruments, motors, and card readers, among others.

Product Portfolio

EZO's main product lines include ultra-miniature bearings, thin-walled bearings, flanged ultra-miniature and thin-walled bearings, miniature thrust bearings, and stainless steel bearings. They also offer metric and imperial bearings for market selection.

Currently, EZO produces 12 million ultra-miniature or miniature bearings every month, with inner diameters ranging from 0.6 millimeters to 95 millimeters. Roughly estimated, for every 100 ultra-miniature and miniature bearings sold worldwide, 75 of them are EZO products.

EZO's developed automated production lines and flexible manufacturing system can meet customers' needs for a wide variety of small-batch orders. In addition to producing standard bearings, EZO specializes in providing customized bearing products to customers.